The Denham Film Studios

Precast Concrete Helical Stairs

The Denham Film Studios are a unique collection of 224 conversion and new build homes, including 154 one-, two- and three-bedroom apartments and 70 four- and five-bedroom family townhouses.

About the project

The main Grade II listed building will be converted into 49 elegant apartments, with two new green squares and communal gardens, bordered by three new four-storey apartment buildings providing 105 new homes. Around the eastern side of the site there will be avenues of new three and four-storey terraced housing, and to the northern section two and three storey detached townhouses, all overlooking communal landscaping and private gardens.

Features within the new development include a retained and restored cinema with bar and a community hall/fitness space. The new properties are designed around garden squares, landscaped grounds, rill water features, private gardens, and protected woodland complete with parking and garaging.

About

Under current plans the retained cinema – which was used to screen movies to Hollywood directors including Stanley Kubrick, Albert “Cubby” Broccoli and Steven Spielberg – will be refurbished and turned into a cinema theatre and club for residents, retaining an important link to the history of the site.

Our Role

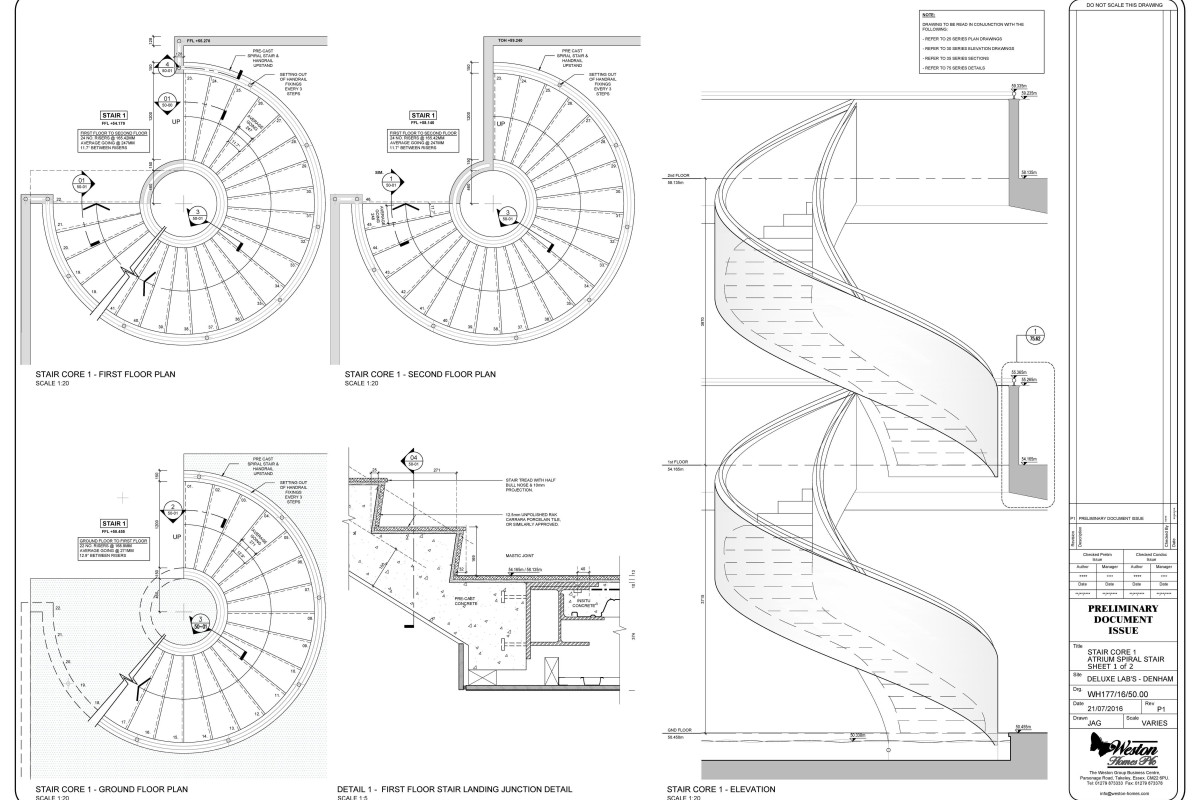

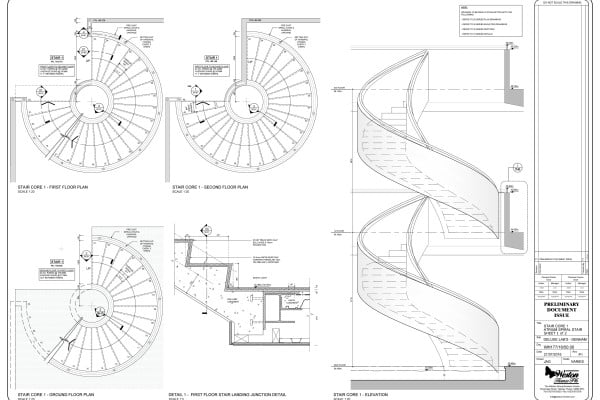

Weston Homes, one of our top clients, approached us to investigate if we would be able to provide two precast concrete helical staircases at our factory in North Essex, incorporating 150mm wide by 900mm high concrete handrails to tie up with the art deco style balustrading to the circulation areas of their flagship development site in Denham.

Constructing these flights in-situ would have proved to be challenging in terms of generating the flowing soffit and erecting the necessary formwork which would have needed to remain in place for at least 4 weeks after the second flight had been cast.

A staircase with a built-in handrail of this size has (to our knowledge) never been made off-site in a factory environment and was a real technical challenge to not only structurally design but to also tie in with the buildings design. There were also restrictions on transport to site and how they would be lifted into position to consider due to the sheer size and weight of each individual flight.

Although immensely challenging, we were completely satisfied with the final result and the effort by the whole bespoke stair ‘Kallisto’ team certainly resulted in a well designed, manufactured and installed finish product.

Weston Homes, one of our top clients, approached us to investigate if we would be able to provide two precast concrete helical staircases at our factory in North Essex, incorporating 150mm wide by 900mm high concrete handrails to tie up with the art deco style balustrading to the circulation areas of their flagship development site in Denham.

Constructing these flights in-situ would have proved to be challenging in terms of generating the flowing soffit and erecting the necessary formwork which would have needed to remain in place for at least 4 weeks after the second flight had been cast.

A staircase with a built-in handrail of this size has (to our knowledge) never been made off-site in a factory environment and was a real technical challenge to not only structurally design but to also tie in with the buildings design. There were also restrictions on transport to site and how they would be lifted into position to consider due to the sheer size and weight of each individual flight.

Although immensely challenging, we were completely satisfied with the final result and the effort by the whole bespoke stair ‘Kallisto’ team certainly resulted in a well designed, manufactured and installed finish product.

Design, Construction & Logistics

We have a long history of providing high quality precast concrete solutions for the construction industry and our experience and reputation led to us being chosen by Weston Homes Plc for this project.

We were able to generate the required soffit using our adjustable pallet system, which also acted as the formwork for each storey height flight. Ducting and fittings for lighting were also incorporated into the concrete walls at this stage.v

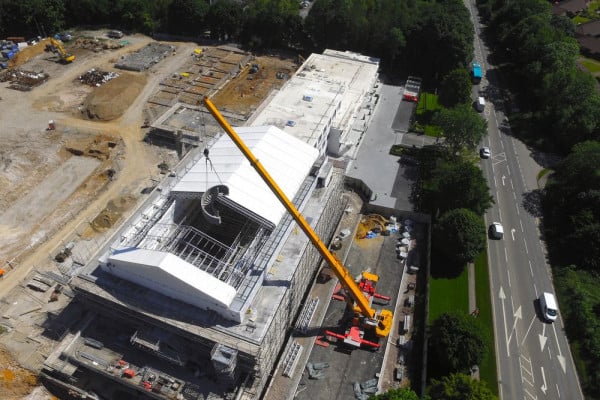

The two 4m diameter flights, each weighing over 11 tonnes, were delivered to site on a low loader and installed in one day by one of our professional fixing teams, minimising disruption on site and providing an immediate access to the upper levels for other trades.

We have a long history of providing high quality precast concrete solutions for the construction industry and our experience and reputation led to us being chosen by Weston Homes Plc for this project.

We were able to generate the required soffit using our adjustable pallet system, which also acted as the formwork for each storey height flight. Ducting and fittings for lighting were also incorporated into the concrete walls at this stage.v

The two 4m diameter flights, each weighing over 11 tonnes, were delivered to site on a low loader and installed in one day by one of our professional fixing teams, minimising disruption on site and providing an immediate access to the upper levels for other trades.

The Developer

Over the last two decades, Weston Homes Plc has continually striven to produce innovative, high-quality homes to appeal to purchasers from all walks of life. Their aims have remained constant; to match traditional skills to the very latest technologies in an on-going desire to produce homes to the best specification and standards possible.

Weston Homes prides itself on achieving the coveted What House National Building Developer of the year 2010 award, which is testament to their commitment and recognition that our quality is second to none in the country.

The variety of developments we have produced is impressive; from traditionally styled bricks and mortar houses and apartment blocks to contemporary ground-breaking designs in steel and glass, ranging from 20 units through to complexes with hundreds of homes.

For more information on Weston Homes PLC, please visit their website by clicking here.

Contact Milbank today

We are experts in precast concrete product design, manufacture, delivery and installation.

Get in touch to find out how we can help you.