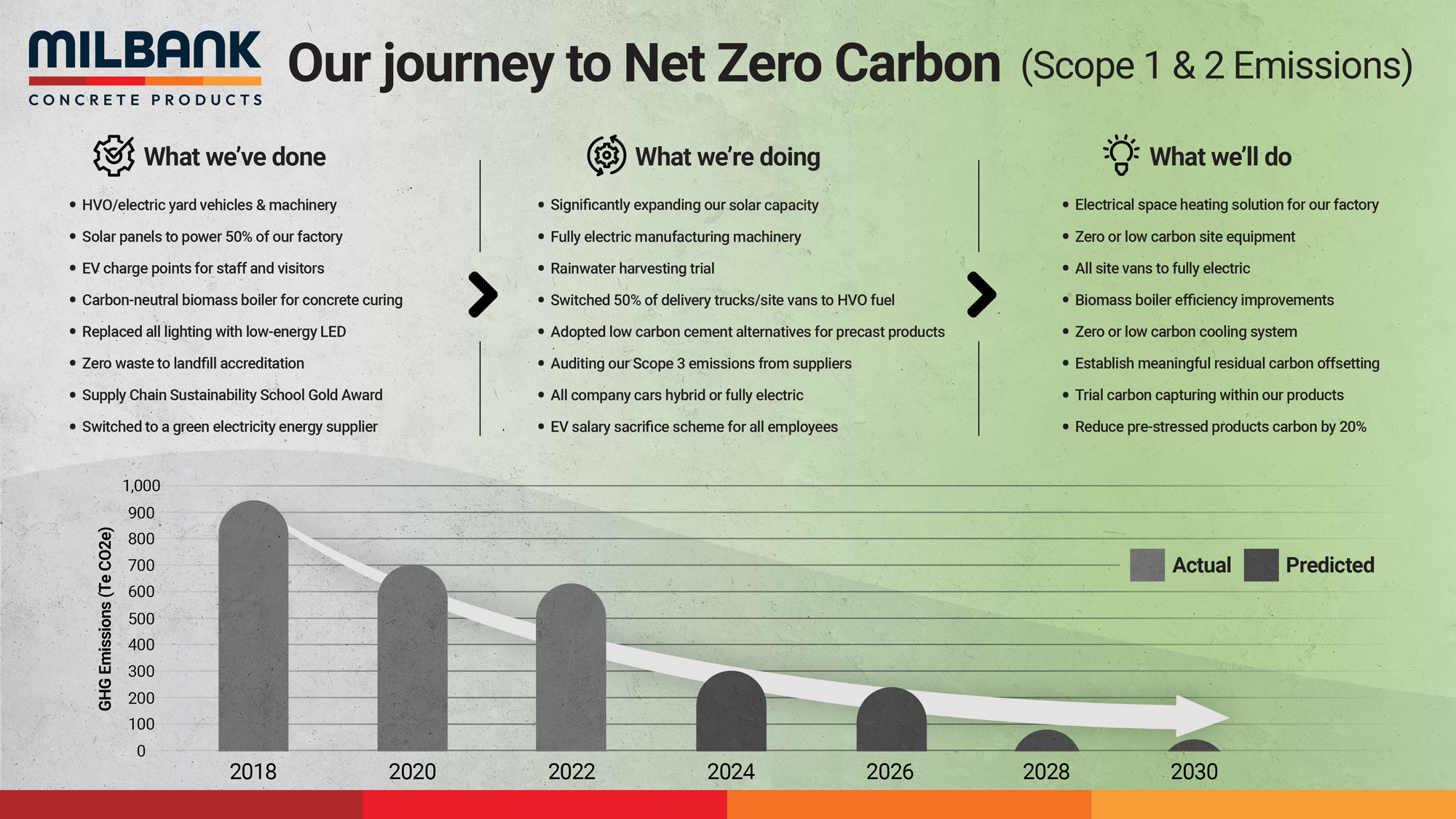

Sustainability

Net-zero by 2030

Our aim is to be the most sustainable supplier of precast concrete products.

We understand that our industry has a big impact on the environment, and that making significant reductions is a big challenge. But we are up for this challenge – we are determined to make a positive difference within our industry and play an influential role in mitigating climate change across the construction sector.

Since 2018, we’re exceptionally proud to have reduced our CO₂ output by 61% down to just 350 tonnes. But this is only the beginning…

We have pledged to become net-zero for our scope 1 and 2 emissions by 2030, 20 years ahead of government targets, and are currently developing our Scope 3 plans.

Low-carbon concrete

All our concrete products are manufactured using cutting-edge cement replacement technology, resulting in a cement reduction of up to 21%, without compromising performance.

We predict that this will result in just over 2,800 tonnes of CO₂e being removed from our concrete products annually. On top of these important carbon reductions, our products benefit from increased early strength, enhanced colour brightness and improved surface smoothness.

Since our reporting baseline in 2018, the change to our concrete mix, introduced in 2024, means that the CO₂e in products manufactured in our Prestressed Factory (Beams and Hollowcore Planks) will reduce by up to 20%. Products manufactured in our Precast Factory (Stairs, Landings, Columns and Ground Beams) have an equally impressive saving of over 33%.

Delivered using renewable HVO biofuel

Our delivery vehicles, in partnership with our haulage provider Woodland Logistics, are powered by 100% renewable HVO biofuel. Based on our current deliveries, we predict a saving of over 315-tonnes of CO₂ annually.

A typical week running a delivery vehicle on regular diesel creates 1,644kg of CO₂ emissions. Switching from regular diesel to renewable HVO produces just 153kg of CO₂. That’s an incredible reduction of 98% per mile travelled.

HVO (or hydrotreated vegetable oil) is a sustainable biofuel derived from sunflower or rapeseed oil which helps us reduce our carbon footprint and support a greener future for our business and the industry as a whole.

To learn more about our responsible sourcing practices and supply chain transparency, read our full statement on HVO sustainability here.

Powered by solar energy

By generating our own solar energy, we’re significantly lowering our carbon footprint, reducing our dependency on the grid, and making a substantial reduction in our emissions.

Our operations benefit from a dual solar installation, with over 800 panels covering both of our production facilities producing on average 306,165kWh of electricity per year. To put that into perspective, that’s enough energy to boil a kettle over 1.6 million times!

The energy produced by our solar panels is enough to power 100% of operations within our specialist precast factory, and around 50% within our prestressed factory, from running manufacturing machinery to lighting and vehicle charging.

Influencing our industry for the betterment of the planet

Sustainability for us extends further than our own actions. We can certainly make an impact on our own, but we can do so much more collaboratively. Our aim is to influence, inspire and encourage our suppliers and partners to follow us on our journey. In fact, one of the ways we measure our success is how we influence those who we work with.

We are proud to have supported our crane partners, Cadman Cranes and Bronzeshield Lifting, with their transition to running on 100% HVO biofuel across their cranes and vehicles. Additionally, we welcomed a similar switch for our supplier of raw materials, Agri-Mix, who have also moved to 100% HVO biofuel for our deliveries. These important switches further reduce our CO₂ output during installations by an additional 400 tonnes.

Our achievements to date

- We transitioned 100% of our production machinery and yard vehicles from the use of regular diesel to HVO – a renewable hydro-treated vegetable oil biofuel. Greenhouse gas emissions produced by our machinery reduced by up to 90%, with a 35% reduction in particulate mass and a 30% reduction of CO₂ company wide.

- We installed solar panels to the roof of our prestressed factory, generating enough energy to power 50% of our manufacturing operations and reducing our national grid dependency by over 25%.

- We invested in renewable energy technology in the form of a carbon-neutral wood pellet fuelled biomass boiler, supplying closed system hot water to our concrete moulds to accelerate the curing process, greatly reducing our process carbon emissions.

- We installed a wide range of electric vehicle charging points for both staff and customers.

- All new company cars are fully electric or Hybrid.

- We developed an intelligent electric curing system within our prestressed factory. This system optimises energy use and saves over 25% versus the previous system.

- We invested in new more energy efficient plant and machinery.

- Our offices, factories and yard lighting all have low-energy LED technology, along with timing and control systems.

- We became an official “Zero Waste to Landfill” rated company, continually managing our environmental impacts and operate an ISO 14001 Environmental Management System.

Managing Director’s Sustainability Commitment

“I am deeply committed to the principles of sustainability, recognising that it encompasses far more than just addressing climate change. As a business, our dedication to sustainability is driven by several key imperatives: ensuring the resilience and stability of our business for the well-being of our employees and their families, actively engaging with and supporting our local communities, and, above all, upholding principles of fairness and integrity in everything we do.

While we have achieved significant milestones in recent years, our commitment to progress remains unwavering. By 2030, we have set ambitious targets for the further reduction of our greenhouse gas emissions, with an aim of achieving a massive 50% reduction from our initial baseline.

We have already embarked on a collaborative journey, engaging with academics, customers, suppliers, and even competitors, as we understand that our shared efforts have the potential to make an immense impact. In summary, our collective actions, driven by these strategic collaborations, hold the promise of contributing significantly to the sustainability goals we have set, ensuring a brighter and more sustainable future for all.”

Lee Cowen – Managing Director

Milbank Group Pledge

We appreciate that all life on earth is under threat of extinction and believe that reducing the harm to our planet is the greatest challenge we face. Whilst we are part of a group of businesses that by their very existence are harmful to the environment, we believe that we can, under our custodianship, not only make a big difference to our impact but hopefully influence others to do the same.

We pledge to use the resources we have – our business, our voice, and our imaginations – to do something about it.

Our guiding principles will be:

- Reduce our environmental impact

- Balance decisions with understanding environmental and social impacts of our choices

- Collaborate with our customers, suppliers, competitors, and other key stakeholders to reduce their environmental impact

- Reduce health and safety risks

- Support our communities to survive and thrive

- Act with integrity by respecting people and human rights

- Report transparently and honestly

It’s no secret that the manufacture of precast concrete is notoriously detrimental to the environment and plays a key role in the production of harmful CO2 emissions produced by the construction industry.

After coal-powered electricity, use of cement is the next biggest emitter of greenhouse gases, accounting for approximately 5% of annual anthropogenic global CO₂ production, with one-tonne of CO₂ produced for every tonne of cement.

Immediate action is required to improve sustainability, reduce carbon emissions and work towards a greener future – and it’s not as difficult as you might think. We understand that our work towards a more sustainable future will never be complete, which is why we are committed to continual research and development that ensures we are always progressing and heading in the right direction.

Process Water Recycling

For the past 25+ years we have recycled the water we use in the production and cleaning process via our Ecofrog Recycling plant.

Once the water has been through the cleaning process, we re-use it in our concrete mixes. On average, only 29% of our water requirement comes from the fresh water supply.

Additionally, we invested considerably in updating and upgrading our site drainage system to include catch pits and new pipe work.

Waste recycling

Like most businesses, we produce waste…and lots of it! We are committed to handling our waste responsibly and take pride in the processes we have in place to deal with the wide range of materials we work with on a daily basis. From concrete and steel to food and office paper, every area has been carefully considered to ensure that we operate as close to a circular economy as possible, reusing and recycling as much as we can.

-

Any waste concrete resulting from our production is processed by one of our waste handling partners. The concrete is crushed into manageable pieces with steel reinforcement separated out. A further process fine crushes the material which is then sold on for use in the road building and construction industry.

-

The steel that has been recovered from the waste concrete and the production process is collected and taken away for recycling. On average, we send 70 tonnes of steel per year for recycling.

-

As with most modern businesses, we are always trying to reduce our paper usage. We separate our paper and cardboard waste from our general waste and recycle it in dedicated waste skips.

-

Wood is used in the precast production process to make moulds and shuttering boards. We also use wooden bearers for storage and product delivery methods. When the wood is no longer usable, it is collected and sent off site for recycling. On average, we send 50 tonnes of wood per year for recycling. Whenever possible, we will also re-use wooden stillage, pallets and bearers in our deliveries and collections.

-

We collect all our waste oil and lubricants in specially approved tanks which are emptied and taken away to be recycled into heating oil. We also operate a strict contaminated waste separation system where filters, contaminated rag and absorbent spill granules are separated and recycled.

-

Any food waste from our on-site canteen is collected and taken to a local biomass recycling centre.

-

All other materials are separated and safely and responsibly disposed of.

Contact Milbank today

We are experts in precast concrete product design, manufacture, delivery and installation.

Get in touch to find out how we can help you.