Milbank Concrete Products invest in solar power

As part of their ever-evolving sustainability strategy and commitment to climate action, in October 2021 Milbank Concrete Products completed a 240kW solar panel installation on to the roof of their prestressed concrete factory to reduce grid dependence and non-renewable, fossil-fuelled, high carbon, electricity provided by the National Grid.

Good for the environment and business

Increasing global carbon emissions from the burning of fossil fuels is having profound effects on the environment, and immediate action is required to prevent the catastrophic effects of climate change. Hotter temperatures, more severe storms, increased droughts, and rising and warmer sea levels, are some examples which have the potential to harm animals, disrupt food supply, displace people, and wreak havoc on our livelihoods and communities. Use of renewable energy technologies, such as solar panels, play a critical role to help reduce air pollution and mitigate global climate change.

Solar power systems derive clean, renewable, zero carbon energy from the sun. Installing solar panels help to directlycombat greenhouse gas emissions whilst reducing dependence on fossil fuels. Traditional electricity is generated by burning fossil fuels such as coal, oil, and natural gas, which emit harmful gases and are the primary cause of air pollution and global climate change. Not only are fossil fuels bad for the environment, but they are also a finite resource. Because of this, the price is constantly fluctuating and can increase in a short period of time.

Since installing the solar panels, carbon emissions have been dramatically reduced and the energy requirements from the grid needed to produce a single tonne of concrete dropped from 11.4kWh/tonne to 8.4kWh/tonne, providing a potential annual saving of 228,000kWh (based on an average annual concrete production figure of 76,000 tonnes).

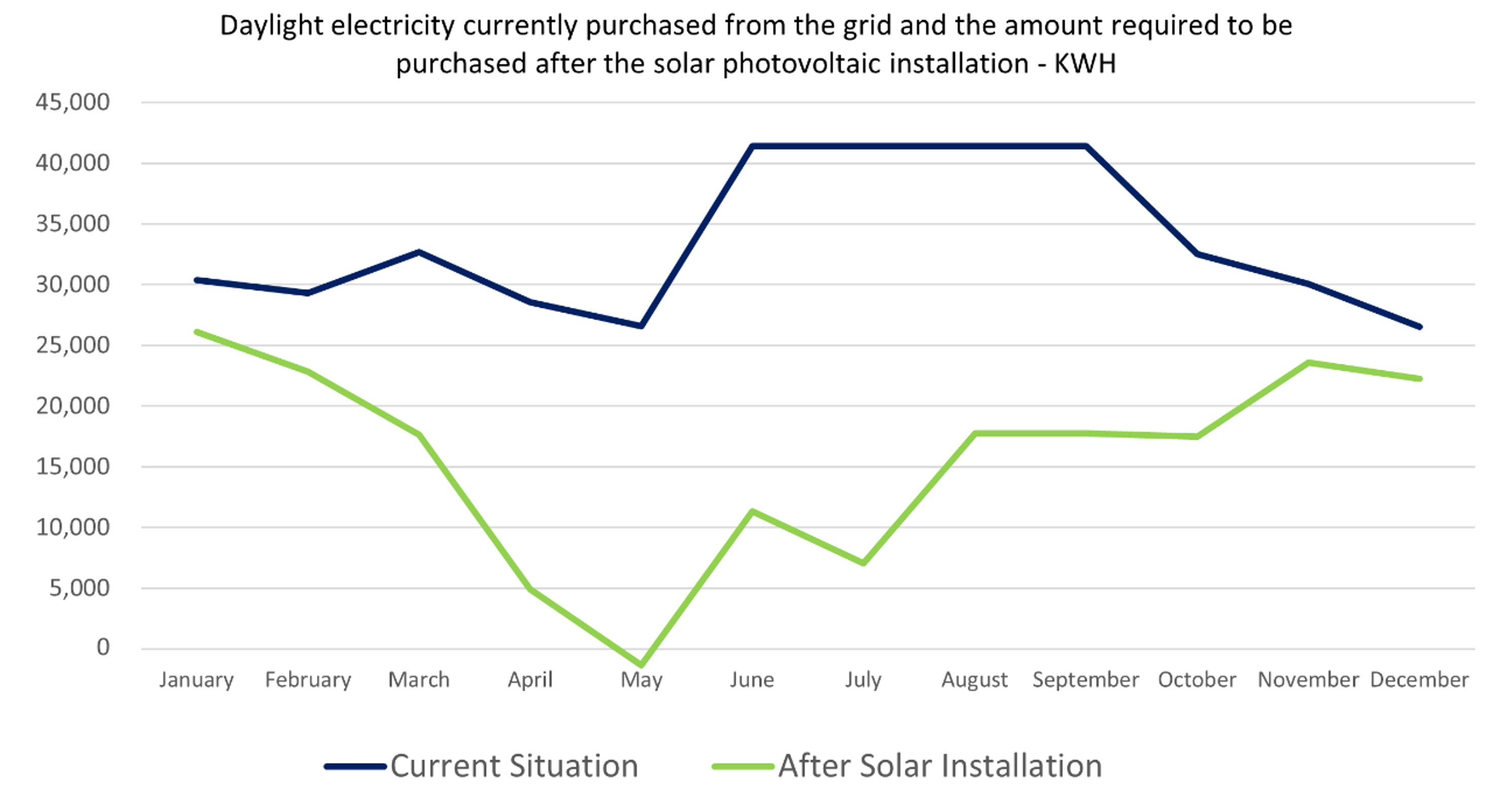

The below graph shows the estimated amount of electricity purchased from the grid (in blue) by MCP to power the factory, versus the potential reduction in annual requirements (in green) after the solar panels were installed.

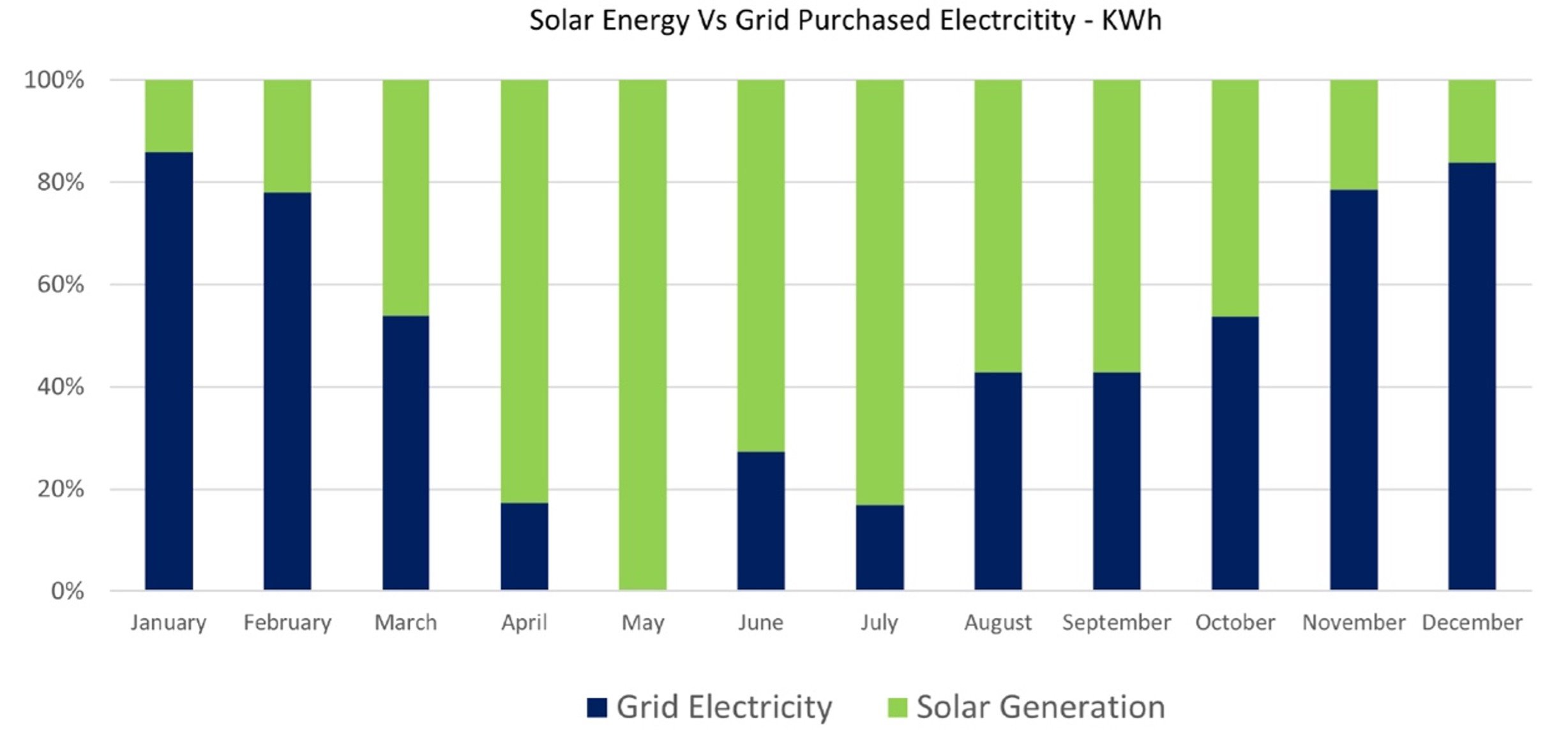

The potential annual savings for the factory generated by the new solar panel installation, along with the estimated dependency on the grid throughout 2022 is shown below. As can be seen, there is a noticeable change once daylight hours/sunlight increases throughout the year, with May predicted to require 0% from the grid and achieve 100% solar electricity use.

|

Energy Gain UK, suppliers of the system at Milbank Concrete Products said, “Following on from their extensive efforts to decarbonise the business, through biomass and energy control systems, the client sought our help to reduce electricity consumption as effectively as possible.

The approach we took ensured that we understood their targets, projected growth of the business and any local grid restraints to design a system that would work favourably for them. The resulting system will play an important part in reaching their sustainability goals.“ |

Milbank Concrete Products understand that their work towards a more sustainable future will never be complete, which is why they are committed to continual research and development to ensure they’re always progressing and heading in the right direction.

Want to work with us? You can contact us here or call us directly on 01787 223931.

Recent news

01/07/2025

Celebrating 10 Years of Support: Milbank & Halstead Town FC

26/06/2025

Supporting Our Armed Forces: Milbank’s Armed Forces Week Fundraiser

18/06/2025

New Product Launch – Milbank GDeck: A Faster, Smarter and More Sustainable Insulated Flooring System