A Sustainable Solution to the UK’s Social Housing Needs

Written by

Lee Cowen, Managing Director

Milbank Concrete Products

17/04/2024

With the ongoing demand for social housing in the UK, the need for sustainable, energy-efficient solutions has never been more pressing.

As housing associations and developers strive to meet the growing demand for affordable housing, they face the challenge of adhering to stringent regulations while ensuring the wellbeing of residents.

On the one hand, the demand for social housing in the UK remains a pressing issue, with thousands of individuals and families awaiting suitable accommodation. According to recent statistics from Shelter, a leading housing charity, over 1.1 million households were on waiting lists for social housing in England in 2022, highlighting the scale of the housing crisis. In Scotland, the situation is equally critical, with approximately 174,000 households registered on waiting lists. As a result, the building of new homes must accelerate in order to meet this demand.

On the other hand, over the past decade, home building has undergone a sustainable evolution, driven by a growing awareness of environmental issues and the urgent need to mitigate the impact we are having on the planet. The climate emergency is an issue which is affecting all areas of the construction sector and finding effective ways to reduce our carbon impact not only helps to tackle the issue, but it can also go a long way to reducing fuel poverty. The National Housing Federation suggests that 15% of fuel poor households in England live in social housing and with the cost of living crisis deepening, this is a problem which isn’t going away.

How can construction in the social housing sector become more sustainable?

The sustainable shift has seen significant changes in material innovation and construction techniques, with a strong focus on eco-friendly solutions. One of the most notable shifts in sustainable home building over the last decade has been the widespread adoption of green building standards and certifications. Entities like BREEAM (Building Research Establishment Environmental Assessment Method) and Passivhaus have gained prominence, guiding construction practices towards sustainability by prioritising factors such as energy efficiency, resource conservation, and reduced carbon emissions.

However, this has meant that the social housing sector has had to adapt its practices to keep pace with the changing landscape whilst juggling the ever-growing need for developing new homes. One of the key challenges facing sustainable home building within the social housing sector has been finding cost effective materials and solutions that are both environmentally friendly and durable – looking at the way a building is insulated is a major factor in driving greener practices.

The current Part L building regulations in the UK state that the U-values, or thermal transmittance, of new builds should be 0.11 W/m²K for roofs, 0.18 W/m²K for walls and 0.13 W/m²K for floors. Whilst the Passivhaus movement requires buildings to achieve a specified U-value of around 0.10W/m²K and no higher than 0.15W/m²K. Meeting these standards is a key consideration for developers.

It’s a fact that 10%-20% of a building’s heat can be lost through uninsulated floors, whilst the Energy Savings Trust has estimated that £40-£65 per year could be saved per household through the installation of effective floor insulation.

WarmFloor Pro provides a eco-friendly option

At Milbank Concrete Products, we’re proud to be a leading innovator in precast concrete products, supplying both the social and private sectors. Over the years, we’ve witnessed first-hand how the sector shifted towards a more sustainable focus, and we’ve adapted our offering to reflect this.

One example is our WarmFloor Pro solution. With its exceptional U-value rating of just 0.08 W/m²K, WarmFloor Pro not only meets but exceeds the stringent requirements of both Part L and Passivhaus standards.

What is WarmFloor Pro?

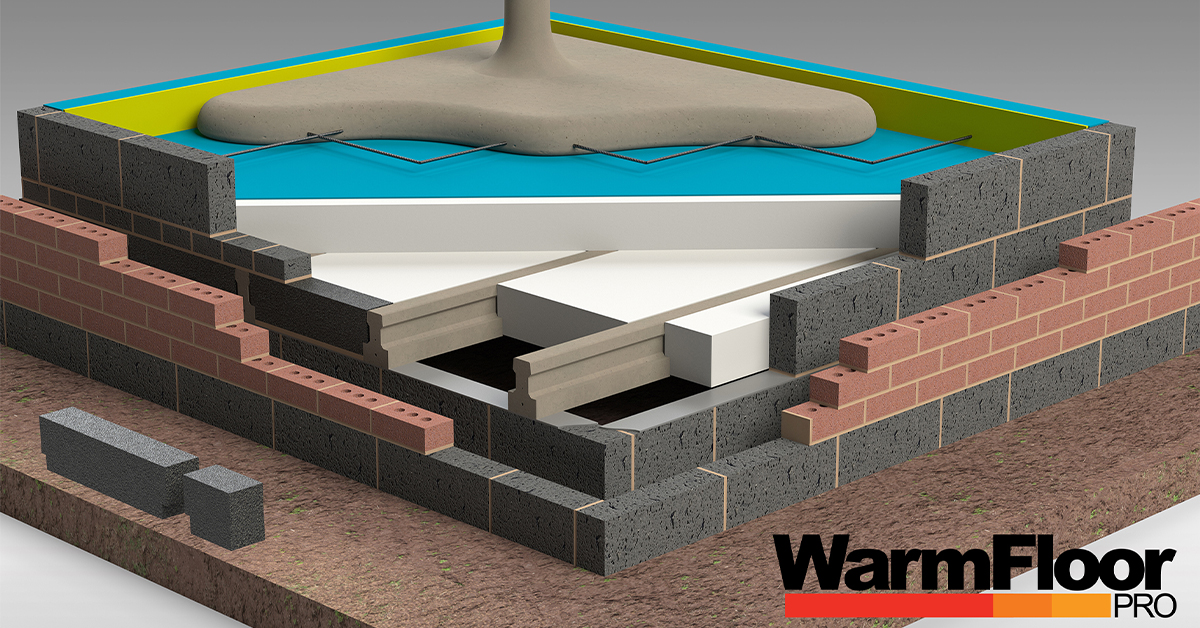

WarmFloor Pro works by replacing standard concrete infill blocks with a combination of rigid insulation modules manufactured from lightweight closed cell expanded polystyrene. These are placed in between our pre stressed concrete beams and finished with an EPS top sheet, damp proof membrane and structural concrete topping. The materials used in its manufacture are 100% recyclable, further adding to the product’s green benefits.

As an alternative to traditional beam and block floor, WarmFloor Pro provides many additional benefits alongside its eco credentials. It is simple to install and provides cost savings of around 20% to developers. Plus, with delivery direct to site, projects can proceed within a timely manner, without the delays which can sometimes be associated with more traditional methods. Both massive ticks when budgets are stretched and timelines are tight.

This innovative solution offers a sustainable alternative for social housing developments, providing superior insulation properties that contribute to reducing energy consumption and combating fuel poverty.

By incorporating WarmFloor Pro into social housing projects, developers can achieve significant energy savings while simultaneously improving the thermal comfort of residents. The durability and longevity of precast concrete products like WarmFloor Pro ensure that these sustainable benefits are realised over the long term, making it a wise investment for the future of social housing in the UK.

To find out more about how WarmFloor Pro could support your sustainability goals, speak with one of our experts by emailing [email protected] or giving us a call on 01787 223931.

Recent news

01/07/2025

Celebrating 10 Years of Support: Milbank & Halstead Town FC

26/06/2025

Supporting Our Armed Forces: Milbank’s Armed Forces Week Fundraiser

18/06/2025

New Product Launch – Milbank GDeck: A Faster, Smarter and More Sustainable Insulated Flooring System