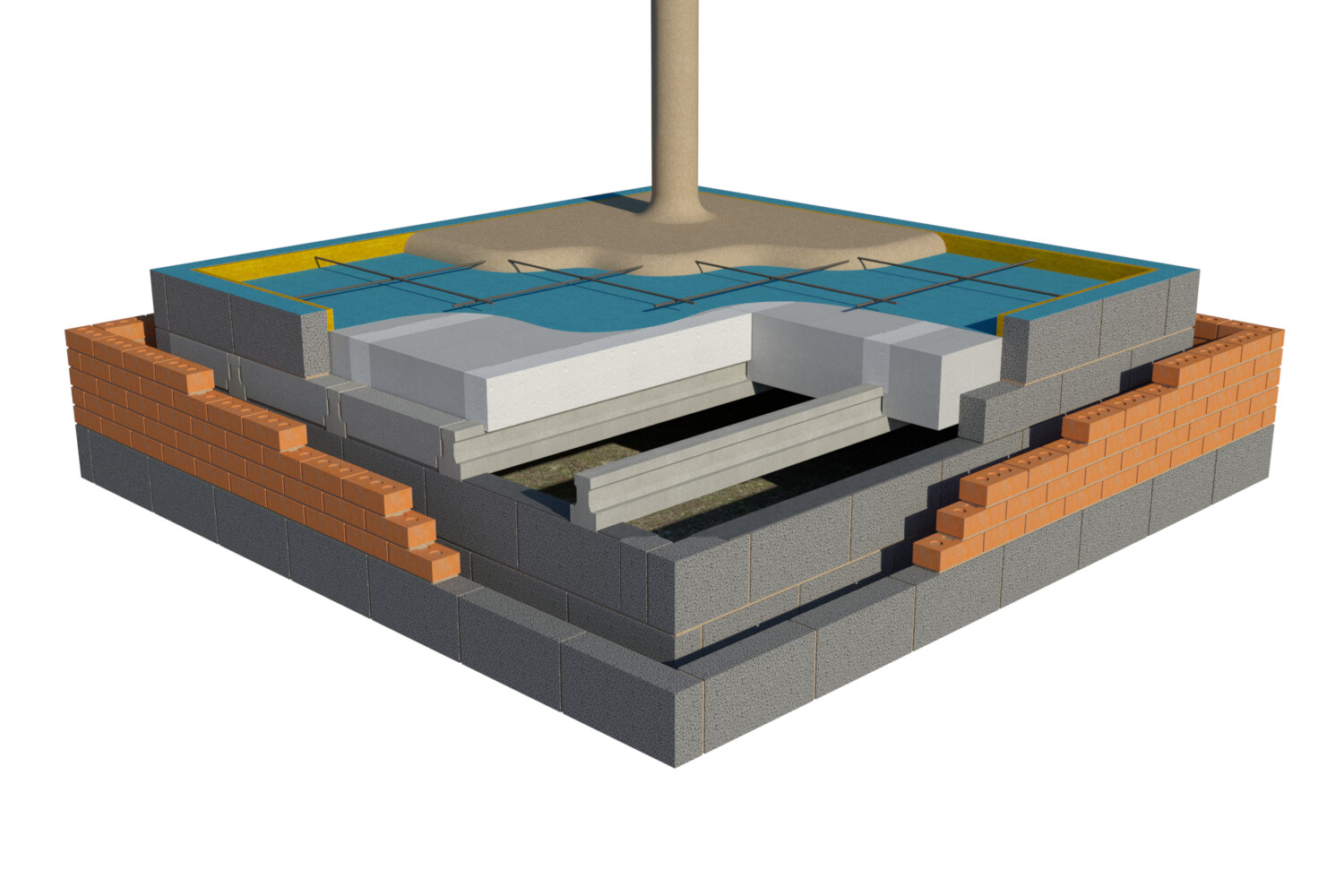

Milbank GDeck thermally insulated concrete floor

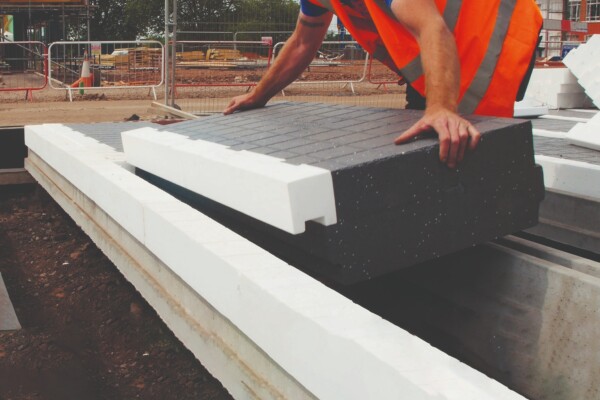

Milbank GDeck is our latest innovation in thermally efficient, insulated flooring systems — combining high-performance expanded polystyrene (EPS) insulation with precision-engineered concrete components. With an integral structural top sheet, it reduces both installation time and on-site wastage, saving you time and money from the ground up.

Why choose Milbank GDeck over Block & Beam flooring?

While block and beam flooring has been a trusted method for years, Milbank GDeck represents a smarter, more efficient solution for modern builds. Milbank GDeck simplifies the process, reduces on-site complexity, and meets current energy performance goals with ease.

Based on an average floor size of 60m², our Milbank GDeck package (inclusive on delivery to site) would cost roughly 43/m² for the GT13 option. Opting for a standard Beam & Block floor (including a 100mm topsheet from a seperate supplier) would cost you roughly £64/m. In this example, choosing Milbank GDeck represents a total saving of over £1,260 0r 32%.

Product breakdown

Concrete Topping

The concrete topping provides the essential structural capacity, load distribution, and a suitable finished surface for the Milbank GDeck system.

Perimeter Strips

The perimeter strips are installed to line the edge of the floor solution, preventing any thermal bridging between the interior wall and the concrete topping.

Structural Mesh

A structural mesh is laid in accordance with the concrete topping specification. (Not included.)

Damp Proof Membrane

The damp proof membrane illustrated is for guidance only. It shall be specified from an external source and installed in accordance with the manufacturer’s instructions.

EPS Insulation Module (Load-bearing Rail)

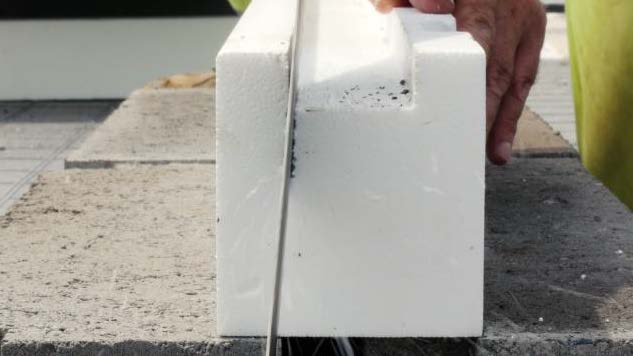

The EPS panels are available in both 275mm and 545mm sizes and are designed to replace your standard concrete infill block.

EPS Insulation Module (Load-bearing Rail)

The EPS load-bearing rails are designed to sit on top of the pre-stressed concrete beams. They are interlocked to an infill panel and come as one unit. Separate load-bearing rails are required when you have multiple beams tight together.

Prestressed Concrete Beam

Milbank Concrete products manufacture both 155mm and 225mm deep lightweight pre-stressed concrete beams, suitable for spans up to 6.5m.

Closure Block

Closure blocks (provided as an optional extra if required) are used to finish the row of EPS insulation infill panels.

Damp Proof Course

The damp proof course is rolled into place onto the base of the bearing wall before the concrete beams are laid to prevent the spreading of moisture from the ground.

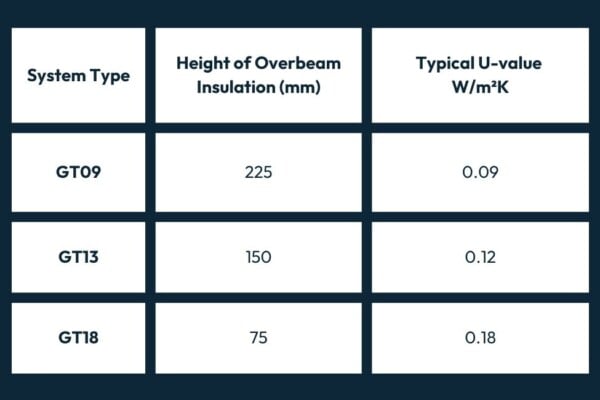

What U-Values can you achieve? (W/m2K)

Milbank GDeck is engineered to deliver exceptional thermal performance, with U-values that can be tailored to meet or exceed current regulatory requirements. Depending on project needs and panel thickness:

- 0.18 W/m²K down to 0.09 W/m²K with increased EPS thickness.

This makes GDeck ideal for new-build developments aiming for low energy use, improved SAP ratings, or Passivhaus-level thermal targets.

Insulated flooring advantages

Making the smarter choice

If the UK is to achieve Net Zero status, we must prioritise reducing carbon emissions from buildings significantly. And what better place to start than from the ground up.

The advantages of insulated floors are proven – with the potential to lose 10-20% of a buildings heat through an uninsulated floor, it’s essential you make sensible choices.

The Energy Saving Trust has estimated a saving between £40-£65 on energy bills through floor insulation, and in combination with other efforts around the home, the savings will add up

-

A+ Green Guide rated, 100% recyclable and no waste created during manufacture. EPS has an ozone depletion potential (ODP) of zero and global warming potential (GWP) of less than 5.

-

The use of EPS for thermal insulation in the construction industry leads to significant energy savings on heating and cooling buildings and a dramatic reduction in the emission of polluting gases. It, therefore, contributes to alleviating the greenhouse effect and acid rain.

-

Expanded Polystyrene is one of the few building materials that can truly claim to be 100% recyclable. It can be reused in the manufacture of new EPS products, soil improvements and auxiliary compost material, as well as being added to other building materials. By fusion and granulation, it can be turned into simple products such as coat hangers and pens.

-

No specialist skills or tools are required for installation – EPS panels are the same length as 5 traditional concrete blocks and are considerable lighter and easier to manage (~2kg).

-

A wide range of EPS panel depths and grades are available to provide the most economical solution for developments whilst maintaining the highest levels of thermal properties.

-

Plastic pegs push into the EPS panels and hold heating pipes in-situ, providing a quick and easy foundation for UFH installation.

Related content

Contact Milbank today

We are experts in precast concrete product design, manufacture, delivery and installation.

Get in touch to find out how we can help you.