About Milbank

Concrete Products

For more than 75 years, we have dedicated ourselves to providing an exceptional level of service within the precast concrete industry. From design and manufacture to delivery and installation, we offer the most comprehensive concrete product service across the UK, providing a range of standardised and specialist precast concrete products.

Our people are at the heart of our business, whether producing a product, quotation, or piece of advice, or supporting our clients and local communities. We strive to be a rewarding place to work where our people are happy, supported, rewarded, and motivated to go the extra mile.

Based in the beating heart of the Essex countryside

Our manufacturing facilities, offices and transport hub are located near Colchester on the border between Essex and Suffolk in the UK.

With the A12, M11 and M25 all nearby, we are well positioned to offer a competitive concrete products service to London & the Home Counties, East Anglia and the Southeast of England.

Alongside our flagship prefabricated concrete products, we also supply an array of specialist concrete products to most parts of the UK. We like to see ourselves as more than just a precast concrete manufacturer. Putting our customers first, we are solution providers, with a mission and vision to deliver a continually exceptional level of service.

Our history

An integral part of the construction industry for over 75 years

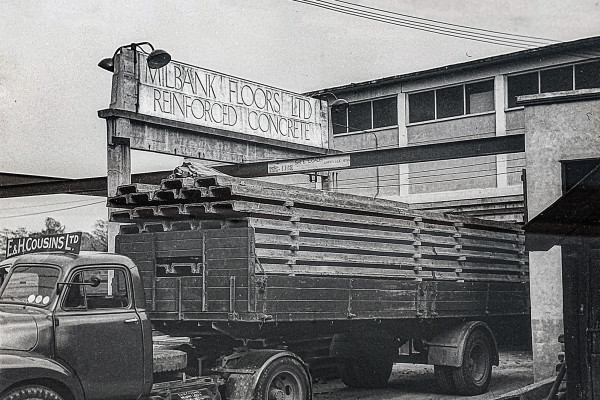

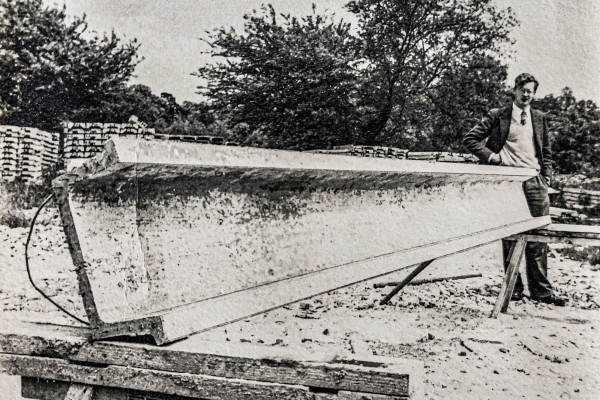

Geoffrey Milbank patents his design for precast concrete reinforced beams and establishes Milbank Floors Ltd. in Howe Street, Chelmsford, Essex.

High tensile wire becomes available and the manufacture of prestressed concrete floor units commence with inverted channel beams and concrete beam and clay pot floors being the initial products. Geoffrey Milbank dies and John and Jim Milbank join the business.

Further investment and development allow Milbank Floors Ltd. to begin the manufacture of precast concrete stairs, providing the industry with a full-package solution.

Milbank Floors Ltd. commence production of a new type of floor construction, comprising 150mm concrete beams with standard building blocks spanning between them. Beam & Block is born. Milbank moves to Earls Colne in 1984.

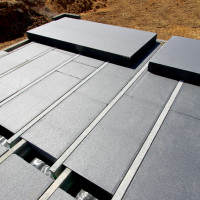

The factory building was extended, a new concrete batching plant added, old moulds removed and replaced with 4 new T-beam beds and 7 Hollowcore beds. Hollowcore production commences.

Additional land is taken on (Yard 2) to create more storage space and build a factory for specialist precast, bringing the manufacturing inside. Precast had been produced outside in Yard 1 until this time.

Sean Milbank joins the business and Milbank Concrete Products Ltd. is born. Agricultural Silage Clamp and Kallisto Curved Stair production begins.

Milbank Group Ltd established following the acquisition of Cadman Cranes Ltd.

Sustainability strategy established and 100% of manufacturing and yard vehicles switched to HVO biofuel – a sustainable alternative to regular diesel, complimenting biomass boiler, electric charging points and water recycling. Chris Pygall joins as MD.

Considerable investment on solar energy see’s 50% of our hollowcore and beam factory powered by renewable energy. Roadmap to net-zero established and monthly reporting begins on sustainability KPI’s.

Lee Cowen joins the business as Managing Director and the company transitions through a brand and messaging refresh. Sustainability strategy continues with an aim of reaching net-zero for scope 1 & 2 emissions by 2030, 20 years ahead of government targets.